Alarms Optimization & Process Safety Assessment Module

Introduction

Processes in the Continuous Process Industry (such as Chemical, Petrochemical, Oil & Gas, etc.) are managed by Control Room Operators (CRO) using Industrial Control Systems. A key component of these systems is the Human Machine Interface (HMI), which displays the status of processes and enables operators to send commands to process elements (sensors, actuators, etc.). Control Systems/HMI generate alarms to alert operators when processes deviate from the operating or design envelope, ensuring continuous safe production.

The widespread adoption of software-based control systems has enabled almost unlimited alarm generation at negligible additional costs. However, this has also led to a negative impact, as high alarm rates can overwhelm operators, potentially masking critical alarms that require immediate attention.

Our Solution

Numerous accident investigations have identified this issue as a contributing factor in cases where operators failed to take necessary action. Consequently, the field of "Alarm Management" has emerged, which is not only linked to basic Process Safety Requirements but has also given rise to International Standards and Key Performance Indices.

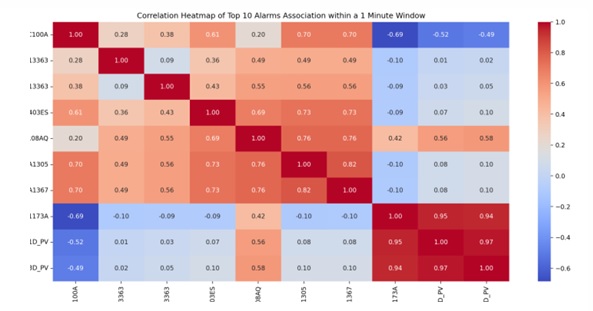

EqualOT lab offers an advanced process alarm and safety event assessment and optimization module that ensures compliance with industry standards and improves overall process safety. By using actual plant alarm data, the solution builds a recommendation system that prioritizes fixes to meet KPIs, which may involve clustering before generating recommendations.

This solution & service includes:

Documentation & Rationalization with templates and libraries tailored for equipment, processes, and states

Real-time audits for alarm configurations.

Process Safety Events Compliance to Cause & Effect Matrices and in accordance with Process & Design Safety Times.

Comparison of Safety Instrumented Functions Demands vs Actual.

Verification of Final Elements Controls.

Auto Testing of Safety Control Elements, Mapping of Cause & Effects Diagram, and Safety Integrity Level (SIL) Studies to standard software format.

Schedule a meeting with us

If you want to learn more about us or have any queries or concerns,

do not hesitate to reach out to us.