GCT is your LOCAL partner for bringing Industry 4.0 practices to your organization. We have unique and rigorous multidisciplinary knowledge, expertise and experience to bring transformative charge to your industry. With our core set of advanced services, pretty much any existing and future industry can benefit in a significant way. We offer unique solutions, locally and at reasonable cost.

EqualOT - Our AI Framework

EqualOT (pronounced as 'Equality')

Introducing EqualOT

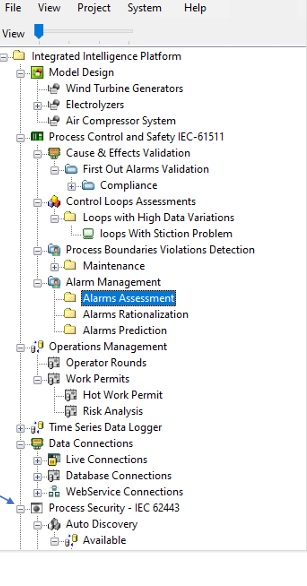

Gulf Crescent Tech's EqualOT software framework includes First Principal Methods and an AI-based engine to guide operation and maintenance personnel in identifying, prioritizing, and resolving problems more efficiently. This leads to:

Reduced operator workload

Improved product quality

Enhanced production

Increased safety

Improved Safety

Greater energy efficiency

The AI engine is designed based on the following steps:

Access sample plant data.

Perform data engineering.

Conduct Principal Component Analysis.

Implement clustering.

Develop a user-friendly interface.

EqualOT Modules

- Services to Industry and R&D Organizations

- Services to Academia

Alarms Management System

We offer an advanced process alarm and safety event assessment and optimization module that ensures compliance with industry standards and improves overall process safety.

Cyber Security Solution

We keep track of your facility's automation inventory, identify vulnerabilities, report deviations from baselines and provide Risk Assessment Score and help in implementing cybersecurity strategies. (In accordance with NIST & IEC 62443 standards)

Specialized Training Services

Process Historian Configurations, Alarms Management as subject, OPC, COM/DCOM, Control Loops Tuning, OT Cyber Security and Analytics with Dashboards.

Process Improvement

Process Safety

Improvement

We present an automated mechanism to address the many issues associated with ongoing SIS Performance ownership. (in compliance t0 ANSI/ISA 84.00.01/ IEC 61511)

PID Control Loops Problem

Diagnosis

We use advanced data-driven techniques to optimize the control loop's performance to deliver the most effective and robust solutions to our clients.

Upgrade To Control Loops, MPC and Others

We have hardcore knowledge to model process equipment as well as design and implement advanced control algorithms. Our hybrid digital twin coupled with advanced controls have the potential to increase your productivity and offering many other benefits.

Digital Twin Based Control, Optimization, Alarming and Predictive Maintanance

With our hybrid and executable digital twin technology, we can perform many types of analysis to increase productivity.

We are the first and one-of-a-kind company in the region providing end-to-end services for advanced academic research. If your research involves end-to end thinking or your want to perform research with a goal to solve a real problem, or to make a real world product – we can be your partner, to take your project to a whole new level.

End-to-end Research and Development Services

We can help in each stage of academic research. We can help in idea conception and generation, grant writing, project planning, system engineering. advanced training , literature review, development of prototypes, lab setup, mentoring and patent filing.

Industrialization / Productization of University Innovations

Many great ideas never see practical use due to lack of time, resource and industrial experience. Our region doesn’t have a ‘Design Firm’ availability as in advanced countries. We are here to fill this gap. If you have an innovation, we can bring it into product form.

Specialized Training

Services

Process Historian Configurations, Alarms Management as subject, OPC, COM/DCOM, Control Loops Tuning, OT Cyber Security and Analytics with Dashboards.

Benefits of incorporating EqualOT

Enabling OT Cyber Security i.e., Protects OT assets against cyber threats, Identifies critical endpoint vulnerabilities & risks, Accelerates forensic analysis & incident response, Enables rapid recovery, Prevents unplanned downtime by integrating data from all the different Levels 2, 1 and 0 systems running in the OT environment, supporting a platform-independent approach, to acquire, normalize, visualize, and analyze operational, system and configuration data from a wide variety of automation system vendors. (In accordance with ISA/IEC 62443, NIST)

Enhanced Plant Monitoring, Fast Problem Detection & Resolution: Conditions affecting safety, quality and throughput are continuously measured and quantified; resulting in improved reliability, decreased downtimes & production losses ($) e.g., Ensuring accuracy, compliance, and improving productivity by providing up-to-date knowledge of SIS (Safety Instrumented Systems) status and providing notifications when problems arise. (In acccordance with ISA 18.2, ANSI/ISA 84.00.01/ IEC 61511)

Enabling a comprehensive context & connectivity on different operational boundaries i.e., Production limits, Safe Operating and Safe Design limits of the physical equipment, Shutdown limits and APC/MPC limits and the Health, Environmental reporting limits. Adding this context is invaluable to understand how changes in one limit may impact the validity of the other limits. (In accordance with API RP 584)

Improved Plant knowledge & Awareness: Institutionalization of updated, online, and contextual information i.e., maintaining a knowledge base of the Operational and Configuration Changes. E.g., MADB (Master Alarm Database) that includes Alarms Description, Alarm Priorities, Alarms Set Point Limits, Corrective Actions, Max. Time to Respond, Consequences, causes etc. available / accessible from operator’s screens. The key information can always be compared against the Control Systems Settings. (in accordance with ISA 18.2, EEMU191)

Secure Operations

Enabling OT Cyber Security i.e., Protects OT assets against cyber threats, Identifies critical endpoint vulnerabilities & risks, Accelerates forensic analysis & incident response, Enables rapid recovery, Prevents unplanned downtime by integrating data from all the different Levels 2, 1 and 0 systems running in the OT environment, supporting a platform-independent approach, to acquire, normalize, visualize, and analyze operational, system and configuration data from a wide variety of automation system vendors. (In accordance with ISA/IEC 62443, NIST)

Safe Operations

Conditions affecting safety, quality and throughput are continuously measured and quantified; resulting in improved reliability, decreased downtimes & production losses ($) e.g., Ensuring accuracy, compliance, and improving productivity by providing up-to-date knowledge of SIS (Safety Instrumented Systems) status and providing notifications when problems arise. (In acccordance with ISA 18.2, ANSI/ISA 84.00.01/ IEC 61511)

Improved Operating Envelope

Enabling a comprehensive context & connectivity on different operational boundaries i.e., Production limits, Safe Operating and Safe Design limits of the physical equipment, Shutdown limits and APC/MPC limits and the Health, Environmental reporting limits. Adding this context is invaluable to understand how changes in one limit may impact the validity of the other limits. (In accordance with API RP 584)

Knowledge Retention

Institutionalization of updated, online, and contextual information i.e., maintaining a knowledge base of the Operational and Configuration Changes. E.g., MADB (Master Alarm Database) that includes Alarms Description, Alarm Priorities, Alarms Set Point Limits, Corrective Actions, Max. Time to Respond, Consequences, causes etc. available / accessible from operator’s screens. The key information can always be compared against the Control Systems Settings. (in accordance with ISA 18.2, EEMU191)

Schedule a meeting with us

If you want to learn more about us or have any queries or concerns,

do not hesitate to reach out to us.