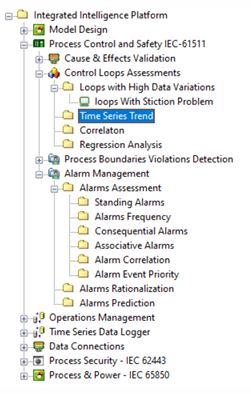

PID Control Loops Problem Diagnosis Module

Introduction

PID (Proportional, Integral, Derivative) control loops form the cornerstone of industrial process control systems, playing a pivotal role in achieving optimal efficiency, stability, and precision in managing complex process variables. equalOT’s control loop diagnostics module meticulously examines loops dynamics and identifies loops problems such as oscillations, stiction, hysteresis, or poorly tuned controller parameters.

Following this analysis, equalOT's team of experienced professionals uses advanced data-driven techniques to optimize the control loop's performance. To deliver the most effective and robust solutions to our clients, equalOT leverages a diverse array of machine learning techniques, including:

Linear Regression

Used for modeling the relationship between control loop variables and process parameters, enabling the identification of trends and patterns that can be leveraged to improve control strategies.

Support Vector Machines

A powerful algorithm employed for classification and regression tasks, helping to model complex relationships between control loop variables and process parameters.

Artificial Neural Networks

Inspired by biological neural networks, these algorithms excel at finding hidden patterns and relationships within large and complex datasets, enabling better control loop performance prediction and optimization.

Decision Trees

A method that recursively partitions data into subsets based on specific criteria, assisting in identifying the most influential factors impacting control loop performance and potential areas for improvement.

Time Series Analysis

A technique for analyzing time-dependent data, which allows for the detection of trends, seasonality, and cyclical patterns in control loop performance, aiding in forecasting and optimization efforts.

Benefits

By applying these advanced machine learning techniques, equalOT uncovers meaningful correlations between control loops and process variables. This empowers our clients with the ability to understand the complex interdependencies among different controllers and process parameters. Consequently, this insight enables them to make precise adjustments to control strategies, leading to substantial improvements in overall process performance and stability.

Schedule a meeting with us

If you want to learn more about us or have any queries or concerns,

do not hesitate to reach out to us.